Welcome to Hebei Chengyu Metal Materials Co., Ltd.

WhatsApp :+8613739610570 Email : sales01@hbcysteel.com

INCOLOY Alloy 825

PRODUCT DETAILS

Keyword: Steel Plate

Incoloy 825 is a nickel iron chromium alloy, which is widely used in petroleum, natural gas and chemical processing industries. It has good corrosion resistance and can operate at higher temperatures than most stainless steels. Incoloy 825 is a completely austenitic nickel iron chromium alloy, stabilized by titanium and added with copper and molybdenum. Incoloy 825 is a general engineering alloy, which is resistant to acid and alkali metal corrosion in oxidation and reduction environments.

The Incoloy825 has the following functions:

Good resistance to stress corrosion cracking.

Good resistance to pitting and crevice corrosion

Good oxidation resistance and non oxidative thermal acidity.

It has good mechanical properties at room temperature and high temperature up to 550 ℃

Certification of pressure vessels with manufacturing temperatures up to 450 ° C

Incoloy825 metallographic structure:

Incoloy825 alloy has a stable face centered cubic structure. Chemical composition and appropriate heat treatment ensure that the corrosion resistance will not be weakened by sensitization.

Incoloy825 Corrosion resistance:

Incoloy825 is a general engineering alloy, which is resistant to acid and alkali metal corrosion in oxidation and reduction environments.

Incoloy825 is widely used in various industrial fields where the working temperature is no more than 550 ℃.

Typical applications include:

Heating pipes, containers, baskets and chains for sulfuric acid pickling plants.

Seawater cooling heat exchanger, marine product pipeline system, acid gas environment pipeline.

Heat exchanger, evaporator, washing, immersion tube, etc. In phosphoric acid production.

Air heat exchanger in petroleum refining

Food Engineering

chemical process

Flame retardant alloy for high-pressure oxygen

Product name | INCOLOY Alloy 825 |

Grade | INCOLOY Alloy 825 |

Thickness range | 0.3mm-3.0mm, |

Width range | 600mm-1500mm |

Length | 2000mm, 2438mm, 3048mm |

Size | 1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, or as required |

Finish | No. 1 , No. 4, hairline , 2b, BA, 8K, embossed, PVD color coated, sand blasted, anti-fingerprint |

Lead time | 7 to 15 working days after the receipt |

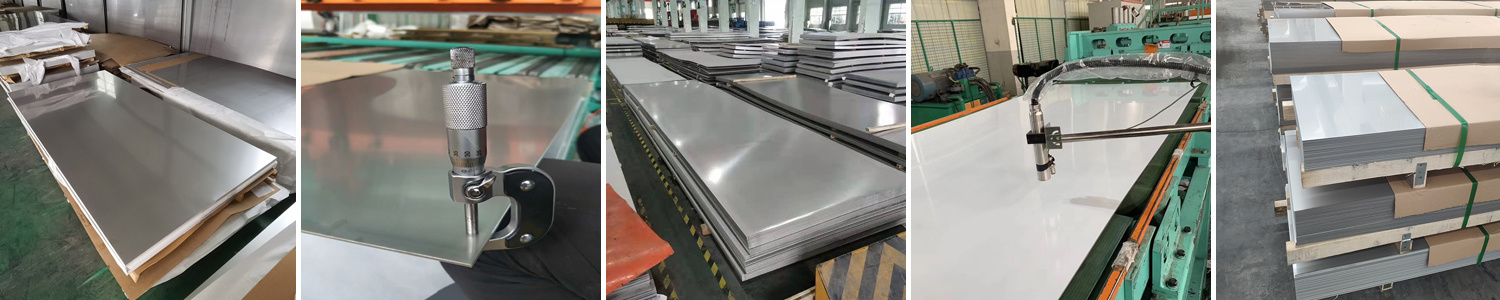

Packing | Wooden pallet or according to customer's request |

Application | Interior/exterior/architectural/bathroom decoration, elevator decoration, hotel decoration, kitchen equipment, ceiling, cabinet, kitchen sink, advertising nameplate |

Grade | Cu | Ti | AI | P | C | Ni | Cr | Mo |

INCOLOY Alloy 825 | 2 | 0.8 | 0.1 | - | 0.02 | 42 | 21 | 3 |

FAQ

Hebei Chengyu arranges and deploys production plan for March

Hebei Chengyu production plan for March 2024

Q1: Are You Manufacture or Trade Company?

A1: We are the professional manufacturer of stainless/carbon/galvanized steel products located in China. Welcome to contact us and visit our factory before you place orders.

Q2: Can I get free samples?

A2: Of course you can. We can produce according to your samples or technical drawings. Contact us by whatsapp or email to get free samples and you will get the sample after 3-7 working days.

Q3: How do you guarantee the quality?

A3: We can send free samples to you, we can accept third-party testing. We also have test certificate, every batch goods will be testing before shipment, and the testing report will delivery to you with your goods.

Q4:How many coutries you already exported ?

A4: Exported to more than 50 countries mainly from Qatar, America, Russia, Belarus, Saudi Arabia, United Arab Emirates, Kuwait, Brazil, Egypt, Turkey, Jordan, India, etc.

Q5:How long is your delivery time?

A5:Within 5 days for stock size, 7-15 working days for customized size.

Q6: Can you OEM or ODM?

A6: Yes, we have a strong developing team. The products can be made according to your request

Q7: What is the MOQ?

A7: If you are scheduling to place a small quantity order or trial order, feel free to contact us, we can meet your requirements.

Q8:What are the certifications for your products?

A8:We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

RELATED PRODUCTS

GET A FREE QUOTE